Metalworking

The company TEROM s.r.o. is focused on a custom and small series production of steel structures for various industries. Our main part of production is subcontracting - frame structures, steel parts and prefabricated units up to 5 tons. The company manufactures based on the drawing documentation supplied by customers or delivers tailor-made solutions according to specific customer’s needs. We work with 3D models in Autocad Inventor and SolidEdge programs. We use drawings in dwg, dxf, stp and other formats.

Our engineering technology comprises material cutting, forming and machining, welding, blasting, varnishing and final assembly (technological possibilities of the company in detail).

Important to us is especially the quality of our production. We have qualified experts in the production workers team. The entire quality management system is certified according to the ISO 9001 standard, welding management according to the EN 3834-2 standard and design and manufacture of welded steel structures according to EN 1090-2. We can supply the constructions in the EXC2 design class.

Our establishment in Chlumec nad Cidlinou has at disposal an area of 7000 m2 for production and storage. Our customers are companies from the Czech Republic, Germany, France and other, mainly Western European, countries.

Reference activities

Agricultural machinery and equipment

We produce and supply components for agricultural machinery including surface treatment, both all around the Czech Republic and into the foreign countries...

More info

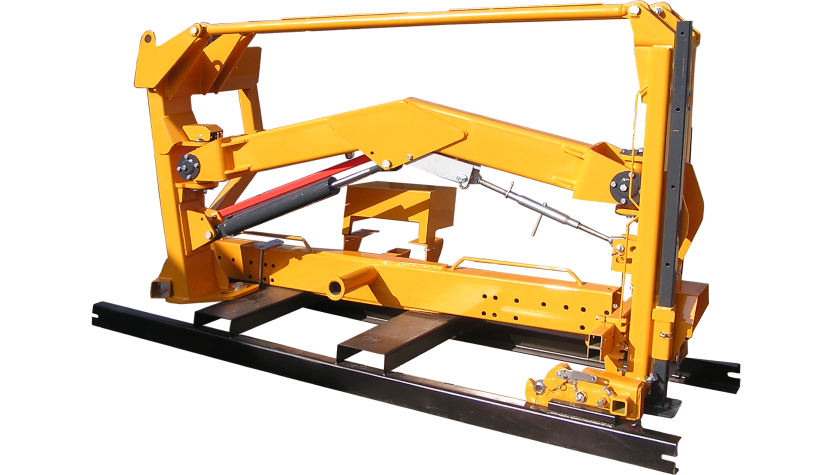

Special vehicles and handling equipment

We manufacture and supply components for commercial and special vehicles and equipment including surface treatment, both all around the Czech Republic and into the foreign countries...

More info

Our products for buildings

We design, manufacture, supply and install steel structures and products for buildings...

More info

Bulletin (PDF)

Bulletin (PDF)

Certificate ISO 9001

Certificate ISO 9001

Certificate EN 3834-2

Certificate EN 3834-2

Certificate EN 1090-2

Certificate EN 1090-2

Certificate EN ISO 9606-1

Certificate EN ISO 9606-1

Ing. Pavla Holanová – Head of Sales

Ing. Pavla Holanová – Head of Sales